Ranch News!

British Car Ranch News For December 2025

Where did it go, 2025 that is? It was really good, but I thought it would last longer!

Scott`s Healey got new floor pans in and welded up. Looking good!

Dave wanted extra heat/noise protection, so we masked off the car and sprayed Lizard Skin heat protection on the inside of the cabin.

Lee`s MGA is moving along nicely. During the brake job it was discovered that each of the original metal brake lines were damaged by overtightening and would have to be replaced. Here is an example of that damage compared to a new metal line.

Mike`s Healey came in with a non functioning overdrive to be diagnosed and fixed. The result of that diagnosis was that it was internal and the trans would have to be pulled and taken apart to find out further info. Long story short, he would benefit greatly by choosing to upgrade to a 5 speed transmission.

Ervin`s Sprite arrived for a condition assessment.

One of the things that happens to slow us down, damaged new parts arriving in shipment. These came from England and were not handled as carefully as I would like. This is a ring and pinion assembly and it has chipped teeth from the long trip. We will have to re-order.

Then the winter temperatures showed up. We have to be selective about when we test drive the cars with daytime temps in the 20`s. First, the roads have to be dry and clear of ice or snow. Then we put on extra layers of clothes for warmth and protection. We are a hardy, dedicated bunch here at BCR! That`s Steve under all that wrapping.

Dave`s MGB is in for assembly after a nice paint job. The first job is to determine what can be re-used and what needs replacing/restoring. The dash pad definitely needs replacing.

Will the new grill fit the re-painted body? Yes, after some massaging and fitting effort it will.

Then all of the brake shoes and drums are removed and will be sent to our specialist to be re-lined, machined and arced to the proper fit.

Stu`s Healey is getting a new Wizard aluminum radiator and electric fan kit. Along with that we will install a manual switch to go with the automatic temperature control.

Rob`s Healey had an alternator conversion installed and is running great with new LED headlight conversions also installed.

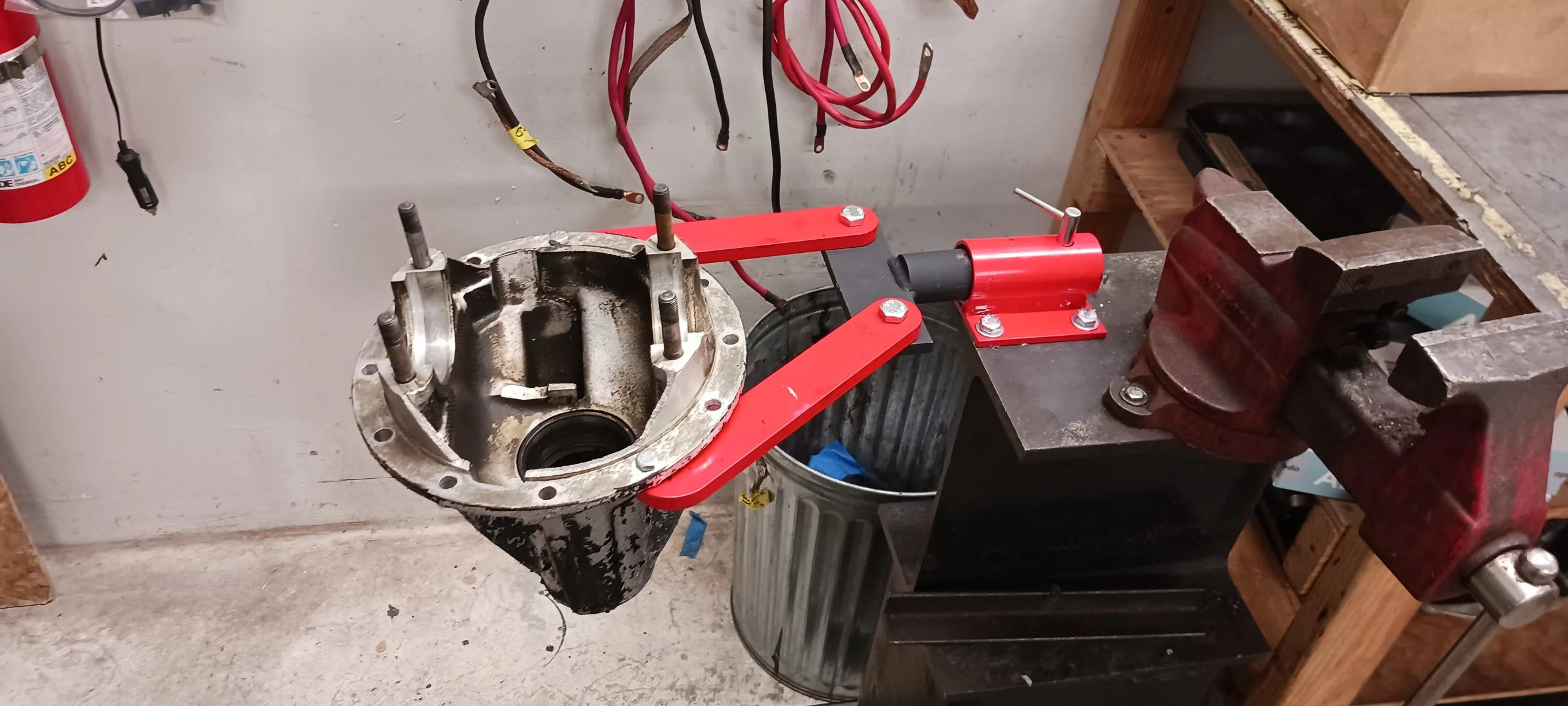

When we have the good part in our possession, we can rebuild the differential by using our new stand to hold it in a great working position.

BRITISH CAR RANCH NEWS FOR NOVEMBER 2025

During the month we had some nice days of weather, so we had the back door open. What a great sight, our local herd of deer were grazing in the pasture not 20 feet from us while we were working away on our classic beauties! Harmony.

We completed work on Ron`s Healey and he got to drive home, all bundled up but happy to be driving!

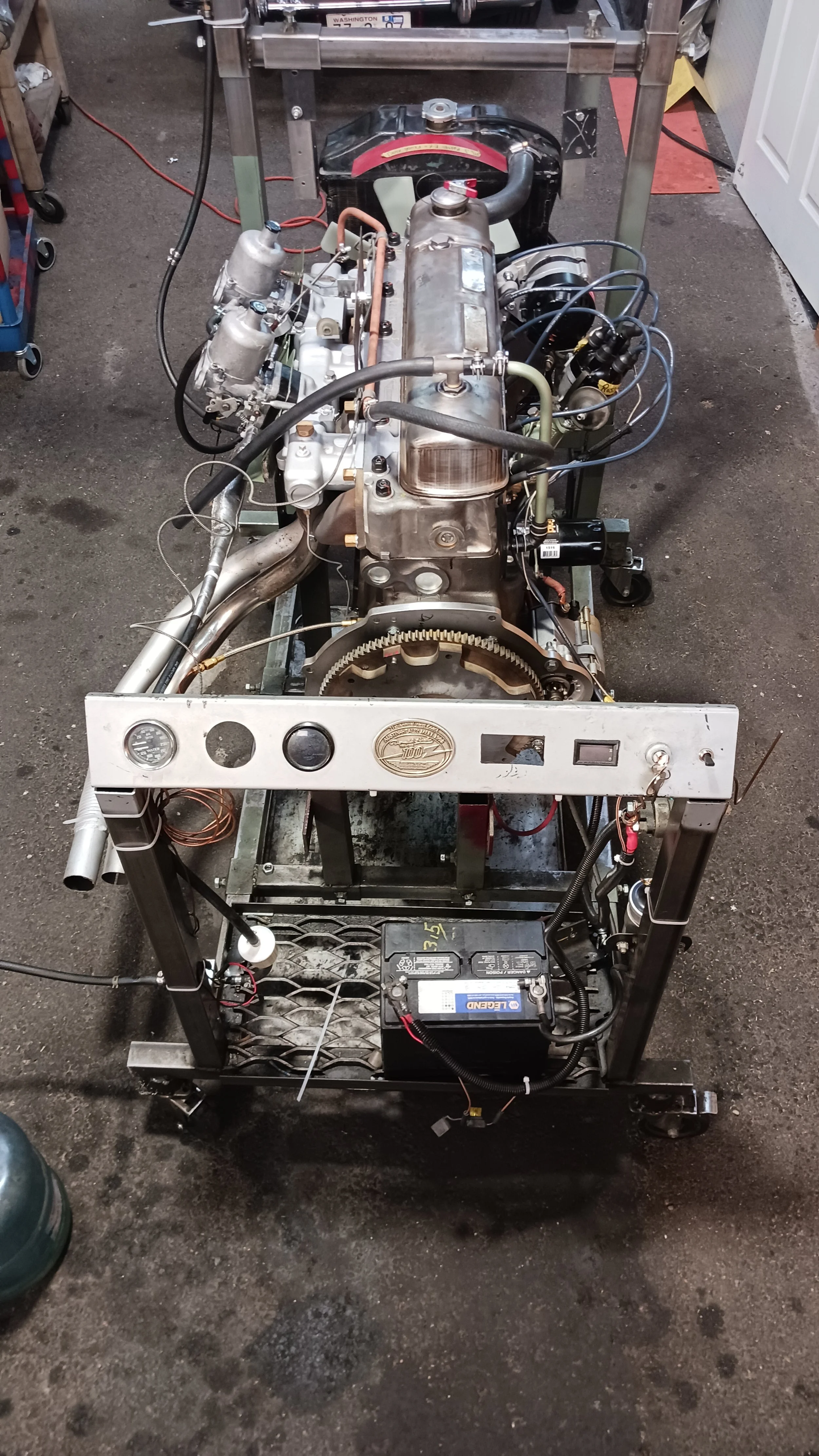

They say things run in three`s, well, here is a case where they ran in fours. Sulley has been busy with engine and transmission/overdrive rebuilds. Here he has three lined up and ready and one in the test sled.

Then later, Sam is working on cleaning and getting Rob`s wheel bearings ready to go in.

Stewarts engine is rebuilt and getting installed in his Healey.

Then later in the visit, Scott got to check in on his Healey paint and body work going on at Tony`s shop.

Eric also trailered in his TR6 for assessment and repair work.

Our job is often an effort of detective work. The clutch system on this car was not operating properly, even after all new clutch parts that are normal during that job. Flywheel surfaced, check. Pilot bushing replaced, check. Pivot shaft and bushings replaced, check. Locater dowels in place, check. Ok, dig a little deeper. Finally, we noticed the drop arm on the pivot shaft looked different than the original. The picture shows the bend in the drop arm not the same as the original, no wonder it was struggling to work right.

And to round things out, we are creating a new workspace here at BCR. We needed a dedicated paint room to do the aerosol painting of parts before we install them on the car. Here Sam and Laurie are working on that project.

Another beautiful local panorama captured here with Cal`s Healey. I was on a test drive doing my quality checks on the almost finished restoration and stopped to get this picture.

Glenn and Joelene were on a trip to visit relatives here in the Northwest and stopped in to visit the Ranch and pick up some of their 100M Healey parts we had restored for them. Glenn and his son-in-law are co-restoring the 100M and needed a shop to help them with the “heavy work”. They picked up the rebuilt differential, and front suspension units on this trip, all crated up and ready to load.

And then Sam and Chasen are installing one in Don`s TR6.

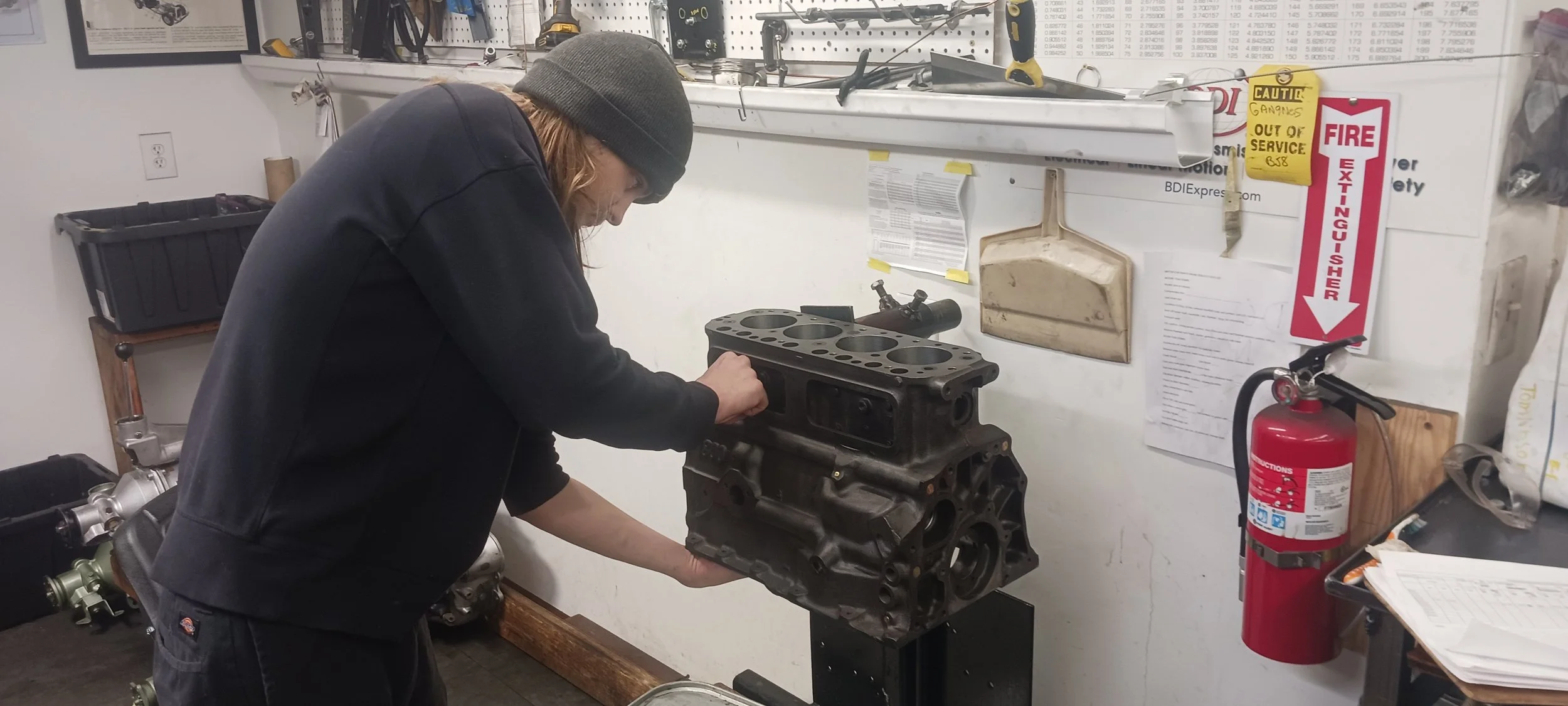

While Sulley switches from transmission work to engine rebuilding on Rick`s MGB.

Chasen has been working on Scott`s Healey differential and needed a special shim to make the rebuild complete. The shim is not supplied anywhere in the known universe. Scott to the rescue! He has a company that fabricates unusual and hard to find parts. He enlisted them to fabricate the shim for this job. They delivered 5 of them, and Chasen has massaged them to fit perfectly in the differential, yielding a perfect job!

During the month, Stuart dropped off his MGB for an oil leak cure and an assessment. Heven forbid, but we found a fuel leak that had developed and solved that too.

Here is a sample of some of the wear we see when working on these classic wonders. This is the hydraulic slave cylinder push rod. This one had been in use long enough to have worn the clevis pin hole oblong and somehow had also gotten bent!

And then look at the position of the throw out bearing locater holes in the shaft; it doesn’t line up either. It has been proven that we cannot take for granted that a “NEW” part is the perfect answer, without some massaging to make it so.

And here is my reward for a job well done during the month. Shop Dog Mini has been watching and approves!

Merry Christmas to all and to all a good night!

BRITISH CAR RANCH NEWS FOR OCTOBER 2025

This is the real October news; last month was labeled wrong and should have been labeled as September!

You may have noticed last month we had a picture of Laurie and her new TR3, but before she and I can start work on that project, we have to get PWee done. Her 71 Midget (PWee) needed a transmission rebuild, and not all parts were available. She chose a 5-speed upgrade kit from Moss. We are putting the final touches on the installation and she proved again, she is not just a pretty face!

Meanwhile, Mini supervises every move in the shop from her favorite chair.

And when we did get it completed, she got to go for the first test drive. Happy woman!

Don`s TR6 came back from Tony`s body shop after getting the convertible top installed and final buffing out of the marvelous paint job. Now we will start the final phase of installation and test driving.

We said goodbye to the white GT6 MKI this month. The new owner lives in Florida and has been looking for a MKI to restore.

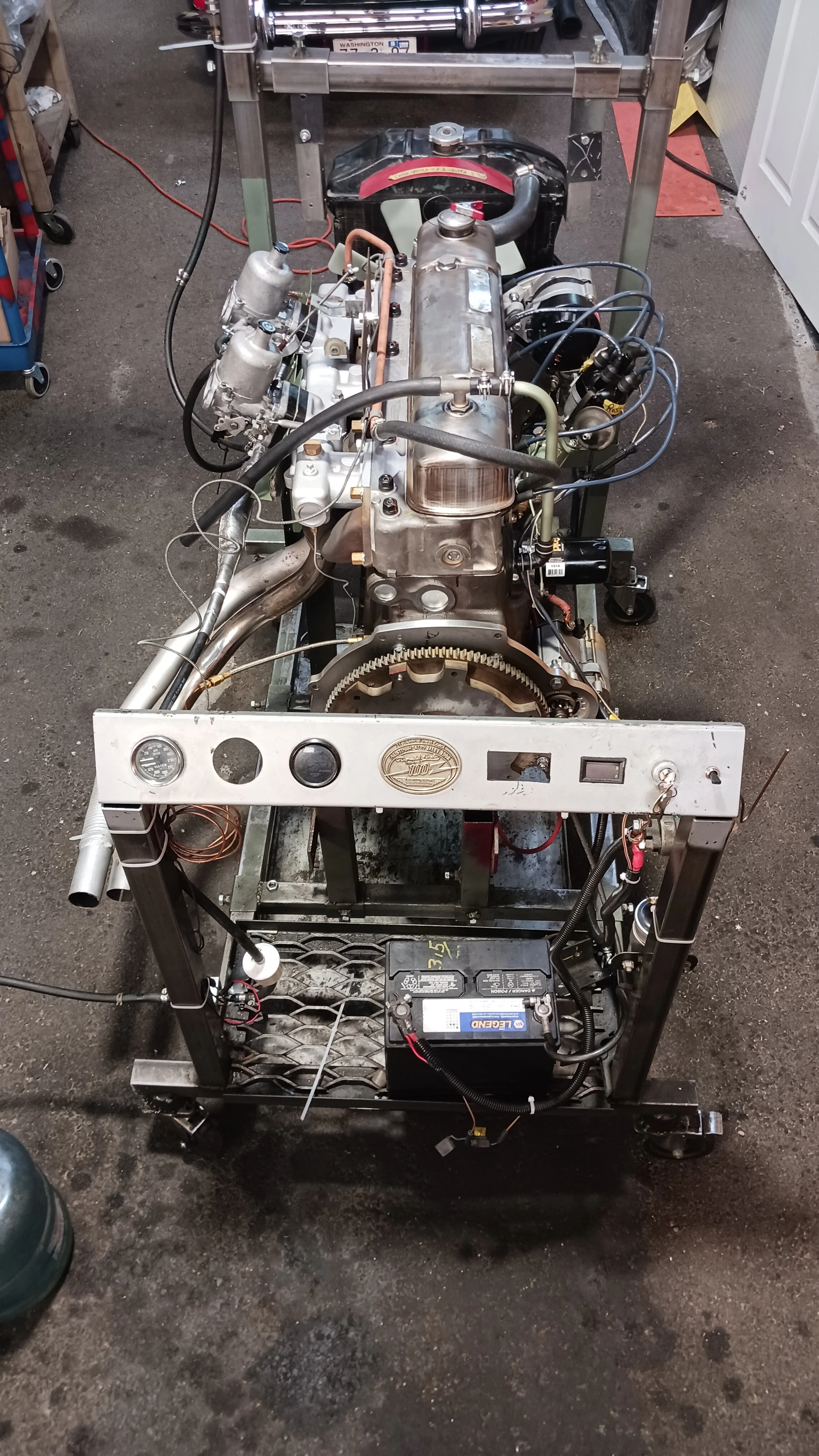

Stu`s Healey engine was installed into the test sled after its rebuild and prepped for first start up.

Tony is a very accomplished air-brush artist too, and we asked him to create a radio cover for the console in the TR6. Nice job!

Speaking of shop made tools, here is the rear axle assembly stand Chasen built. It allows him to do the restoration work on differential assemblies safely and conveniently. It is made to adapt and accept 3 different brands of differentials.

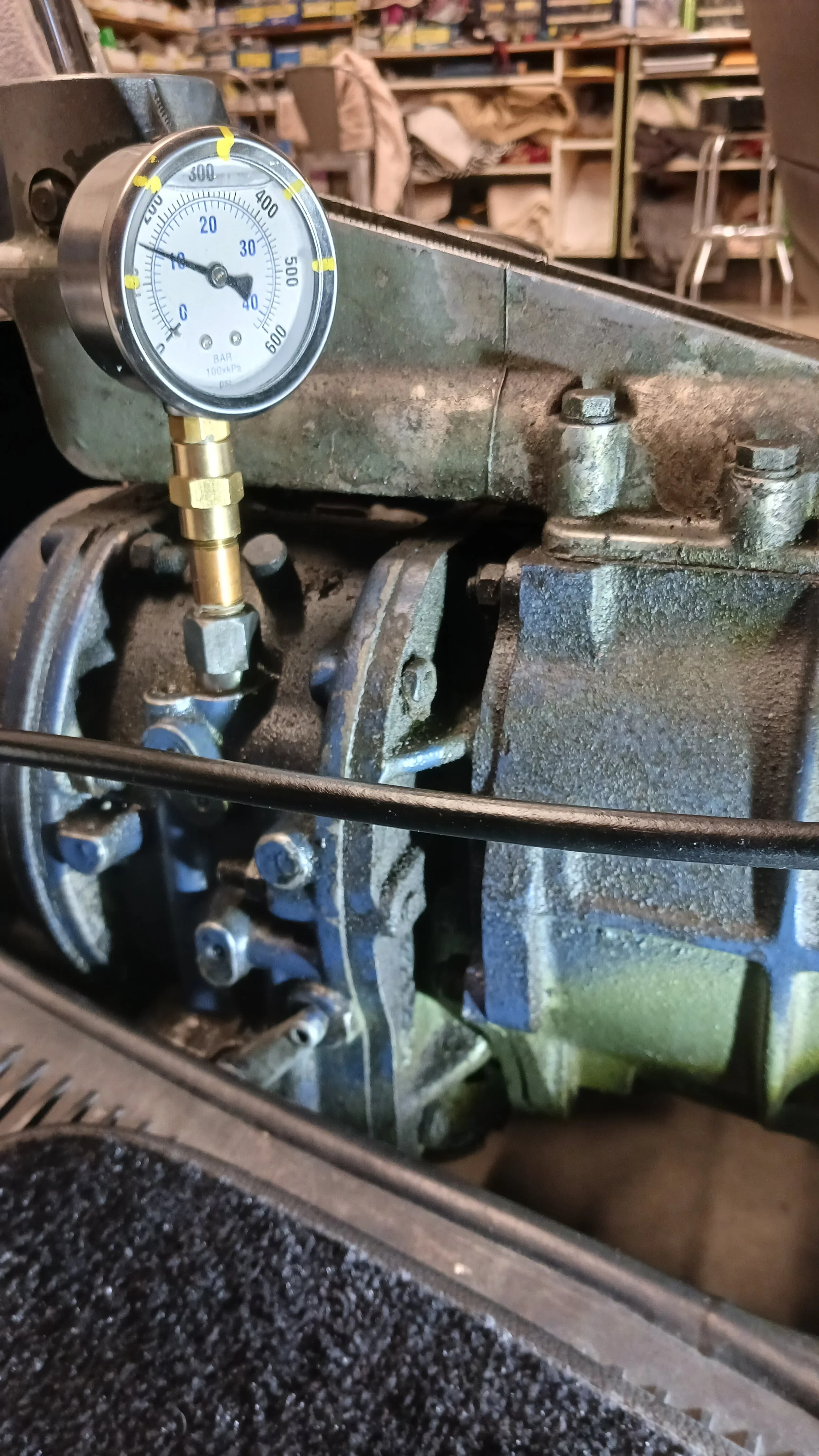

The final test after a rebuild and the first test on a car exhibiting overdrive issues is to remove the trans tunnel and install our pressure test gauge to the overdrive.

And here is Sulley rebuilding a Healey transmission in his dedicated assembly room.

Then we can read the amount of pressure the overdrive is creating and determine if the rebuilt unit is operating well, or if the original overdrive with a new problem is caused by low pressure or adjustment of the solenoid.

While Chasen is in his restoration room repairing the vinyl covering on a Healey door armrest.

Mike`s Healey is in the middle of his yearly maintenance visit. Now the headlights work on high beams, with our special LED headlight upgrade.

Rob`s BN1 Healey came in, and we started on his list of yearly maintenance.

Cal`s Healey transmission and overdrive are heading for the test sled to check operational functionality before it can be installed in the car.

Ron`s convertible top had some points where rain would get in. Being a common problem, we have created some special fixes and applied them to his car. This is the final test, a good rain soaking with Chasen inside watching for results.

Bob`s MGA is really getting close to the finish line. We have invited him to come to the shop and take the car for an extended test drive, so he can approve and note any additional changes he may want before we call it done.

Rick`s MGB engine came back to us from Action Machine after getting all of the machining done and will be the next project for Sulley to assemble.

The team here at BCR wishes you and yours a very happy Thanksgiving holiday!

BRITISH CAR RANCH NEWS FOR SEPTEMBER 2025

Yes, the fires are close, 13 miles away, the real problem is the constant smoke and ash falling out of the air! There are several fires burning in the area, and we seem to be epicenter for the smoke and ash, with a steady stream of water toting helicopters and water scooping planes directly overhead all day. The parts per million ash have been bad enough on 5 days to shut the shop down for health reasons, so production suffered too.

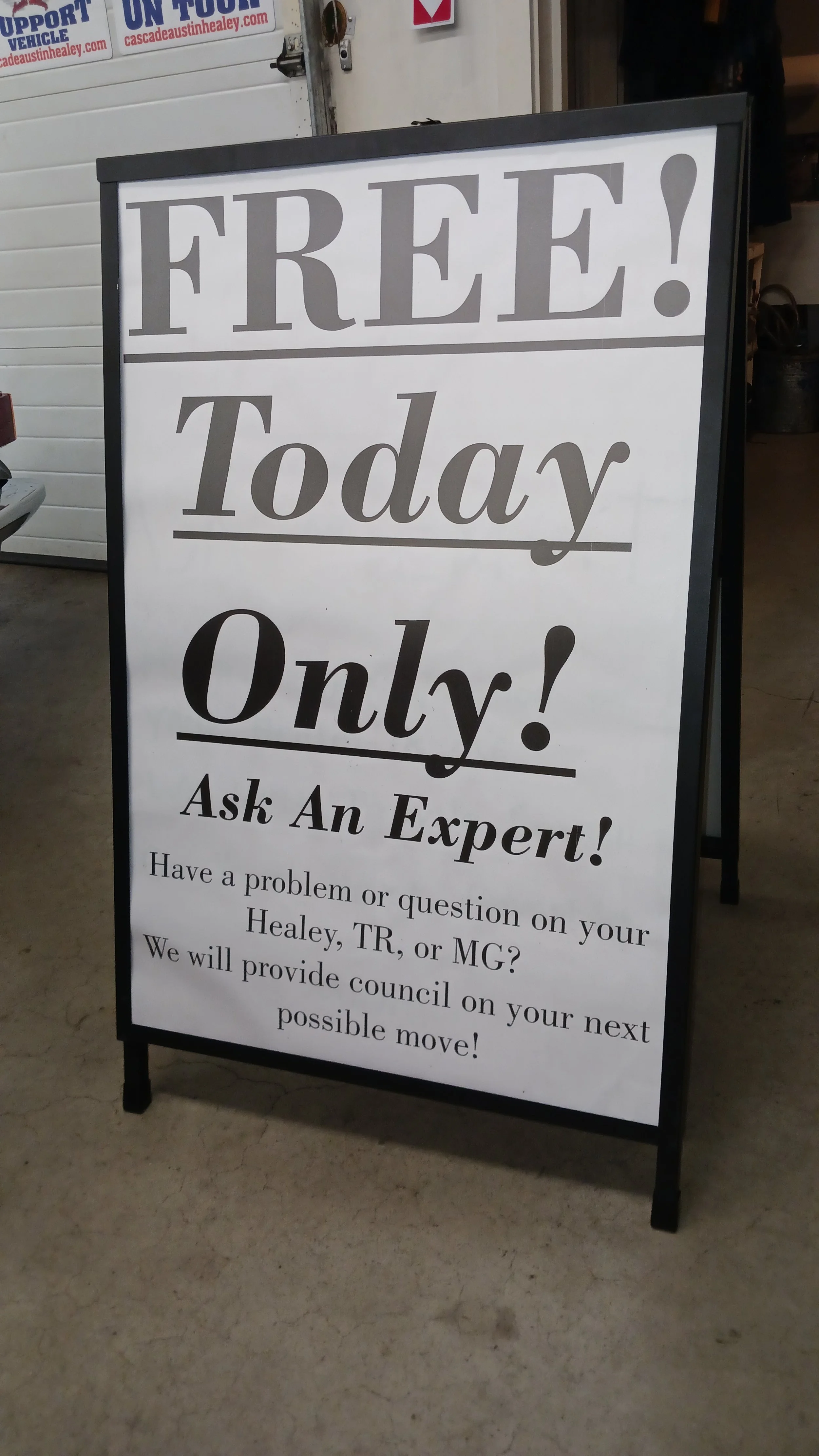

Laurie and I were also away from the shop in October. The annual Triumph meet was in Port Angeles for a week, and the annual Healey meet was in Chelan for 4 days. I was a presenter for several things at both events. For the first day of the Healey meet the whole shop joined me and we put on the “Ask the Expert Drive Through Tech Session”. We had 25 cars come through and get advice as to what the owners next move should be on a problem with their Healey.

The next biggest news is Laurie`s new car! A new client wanted his TR3 to be assessed and find out what the car needed and thereby make the decision to invest or sell the car. The TR3 had been in storage for 10 years and needed quite a lot of repairs to get safely back on the road. Laurie is the new owner! She has wanted a TR3 to bolster her stable of cars and it happens to also be the first British car she owned in high school. Not to worry, this car will be a together project for her and me on weekends.

Cal`s Healey received a new tonneau, installed by Laurie and Chasen.

Stu`s Healey engine rebuild was completed and then installed into our test sled to start up and begin the break in process.

Glenn`s Healey got suspension assembly and rebuilding the carbs. His engine also was transported to Action Machine in Seattle for heavy work to be done.

Mark`s GT6 got a rebuilt differential and overdrive, in addition to some rear suspension work done.

Bob`s MGA moved closer to completion with Sulley installing the engine accessories after an engine rebuild was completed.

Scott`s Healey received new metal in the passenger area, after rebuilding both the front A post and rear B post assemblies. Lots of cutting out and welding in new pieces that Tony builds right in his shop.

Mike came in for his yearly list of to-do`s on his Healey. He just completed a 2,000-mile tour of the Ozarks and a week in Branson for the East Coast Healey meet.

Ron also had an appointment for his Healey`s yearly maintenance.

Dave has had a dream of completing a restoration on his MGB that was started and interrupted. He found us and entrusted us to do that job for him, and the car arrived via trailer with a nice complete paint job and lots of boxes of parts!

Rob has an exceptional early Healey that he wants to have assessed for needs and perform routine maintenance on. His car arrives this month.

Bob has owned his TR3 for 50 years! It has been with him through thick and thin, towed to each new home he moved to, and cared for along the way. It is time for a new wiring harness and needs assessment and then catch up on maintenance. This pix was taken at the Wenatchee to Seattle shuttle station that many clients use to travel back home on. The reasonable cost and varied schedule make it a good choice.

Sulley is working on another transmission/overdrive rebuild (Scott`s Healey), in the engine/transmission room.

While not a new tool, the engine test sled deserves a shout out! It is one of our more used tools and really helps begin the break in process on a rebuilt engine we have done, (Stu`s Healey).

Sometimes you have to go under cover (literally!), to find the problem. You can just see Chasen`s back in the doorway.

That brings us to the next big news for the shop; we found Sam! Sam is a young friend of Chasen`s and has been interested in working in a restoration shop and learning all he can about cars and how they work. We have agreed to give him a shot as our shop cleaner to give him the opportunity to do just that, starting at two days a week. He is a very quick study and has a positive personality and has already pushed that to 3 days a week. Then he started picking up the mechanical side a bit by being the extra hands to assist the mechanics during the day. He is up to 4 days a week now. What a great addition to our family!

Until next month, Laurie, Christopher and I wish you many miles of British Car driving!

Oh, one more thing. Do you know anyone that would like to buy a Mad River solo whitewater canoe?

Ranch News July 2025

The big event this month was the ABFM in ST. Edwards Park on July 12th. British Car Ranch had a vendor booth set up again and all hands were on deck for the day. We made many improvements to our booth this year and doubled the attention we received from the participants. One of the big attractions was modifying our “Drive through tech session” for the day. We had a reader board announcing free technical advice on your car. That kept all of us busy all day long!

Ron entered his Healey BJ8 in the show, his first car show since we completed a frame up restoration on it. The car placed first in it`s class, congratulations Ron!

Back in the shop, Don`s transmission was completed and installed.

Bob`s MGA engine was painted and ready to install.

Don`s TR6 had our custom 3rd brake light installed on his restoration project. Almost ready for test driving!

Scott`s Healey had the door hinge post area rebuilt and then the front shroud, front fender and door were gapped and aligned.

And when the installation is complete, it looks like this, just like its` later brother the Healey BJ8.

Bob and Nancy own an early Healey that we did a refresh on years ago. They stopped by to visit their grandson Cooper during the month and also to take a look at their son Chris` Healey that is currently in its`restoration process. Cooper is the summer apprentice that has joined us from McPherson College auto restoration course in Kansas.

And finally this month, we have a project car for sale. Bill has owned this Triumph GT6 MK1 for many years and was hoping to do some light maintenance and return it to daily driving again. The car needed all that light maintenance and then an engine rebuild was needed and even more maintenance, putting it beyond his intended scope for the project.

The engine has been pulled and prepped for a rebuild, so it would be classed as a non-running project car. Asking price is $4,500. To get further details and pictures, contact us at britishcarranch@hotmail.com

Cal`s Healey is nearing the end of a multi year complete restoration by us and we brought it to be the show piece at our booth for the day, and drew a flood of attention.

Time to pack up and head home

Mark`s GT6 had the transmission and differential removed for service work.

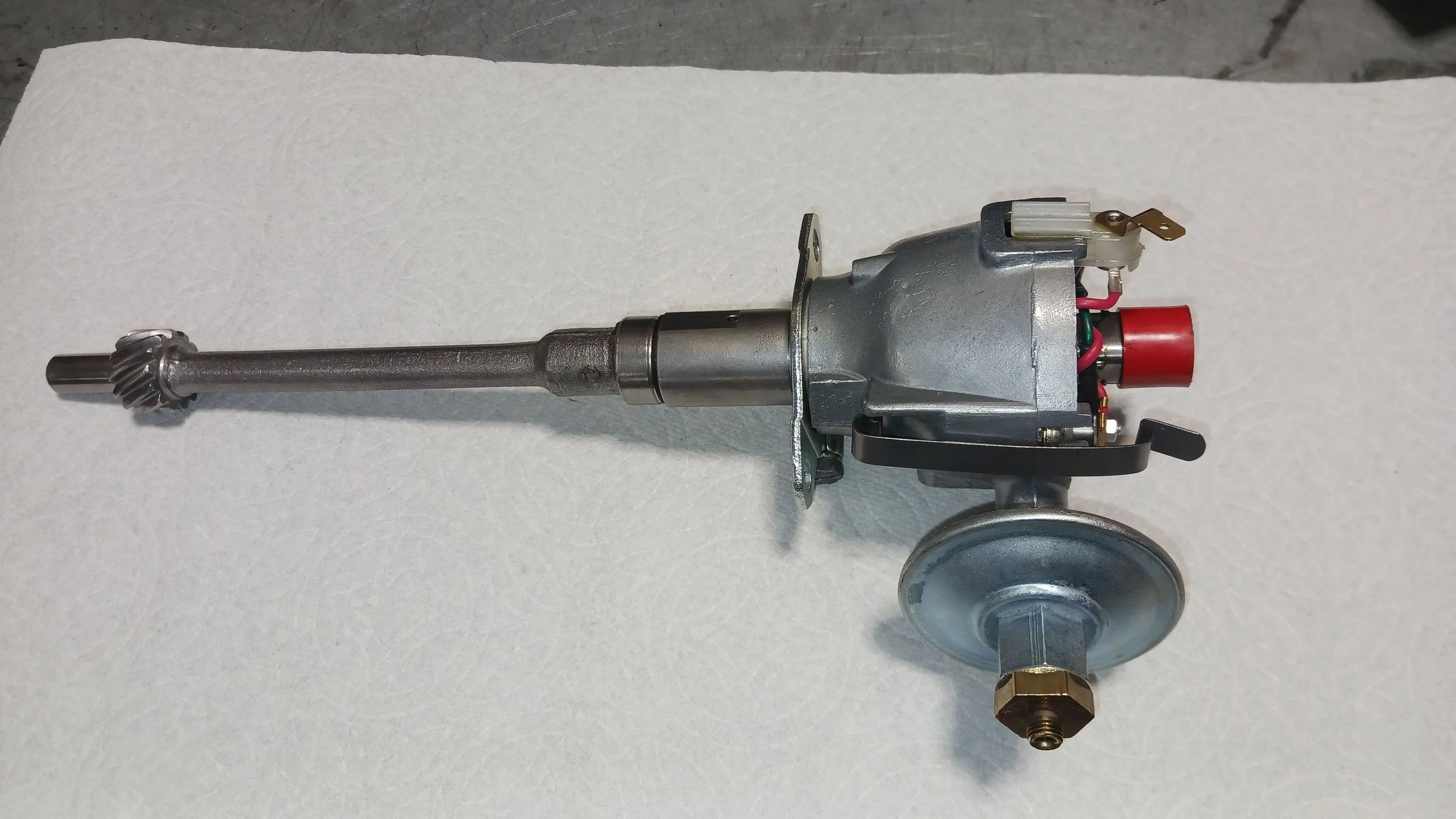

Henry`s factory 100M was diagnosed with distributor issues and sent to Advanced Distributors for a complete rebuild and calibration. Isn`t that beautiful work he does! He solves problems elegantly.

Mike`s Healey came in for yearly maintenance.

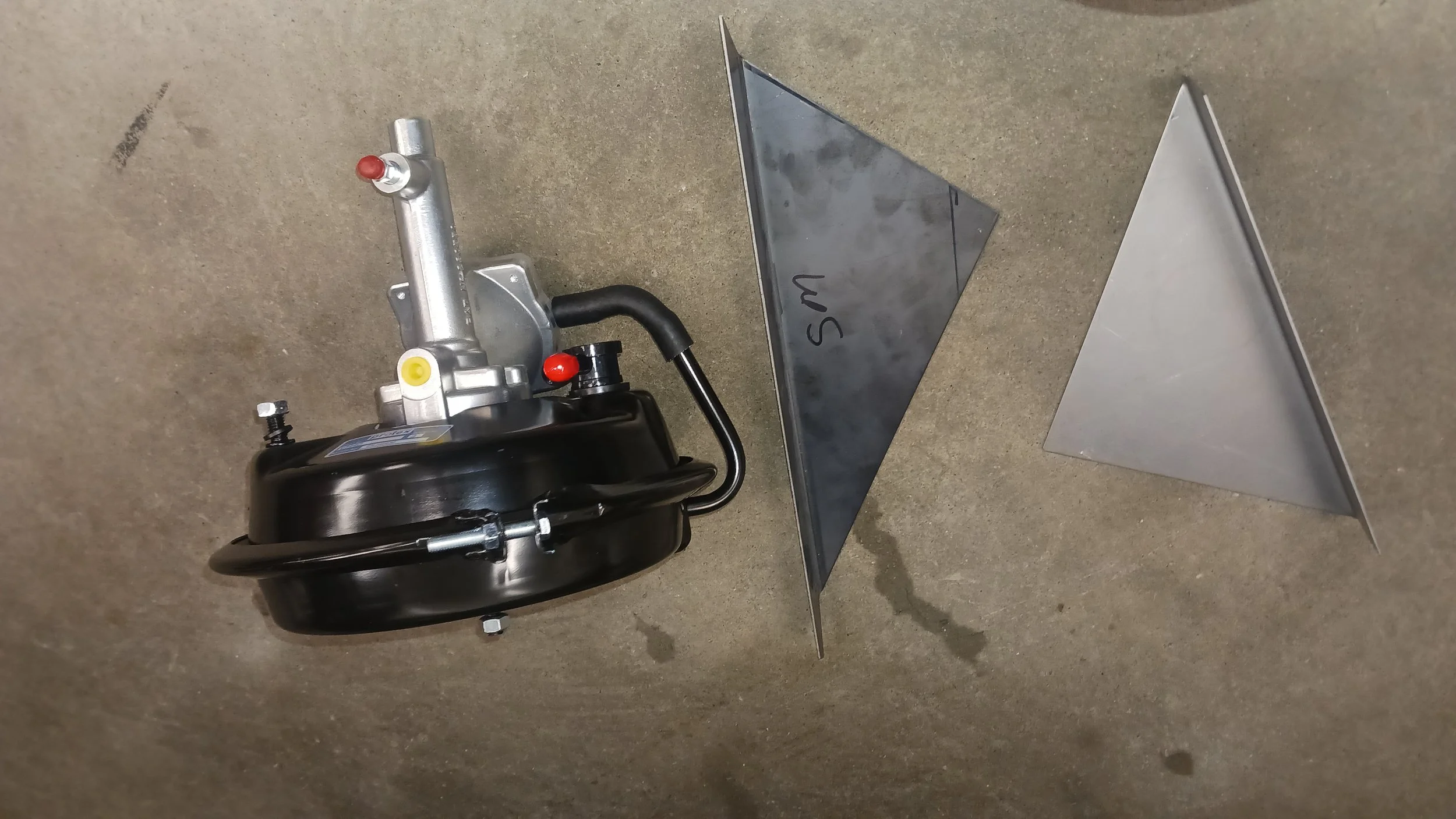

We have developed a process to add power brakes to the early standard brake Healey`s. Here are the main ingredients, the new servo that is sized perfectly for the Austin Healey, and the custom brackets we have fabricated here in our shop.

To make the new hydraulic brake lines requires a special tool and expertise. We have just updated our flaring tool to a hand-held hydraulic unit. Boy is it terrific!

Bruce`s Healey is in for its yearly maintenance and a new wiring harness.

A SPECIAL EDITION OF THE BRITISH CAR NEWS

I have seen and heard a lot of comments about what the future looks like for our British Classics. Many opine about the retiring mechanics, shops closing and no one interested in taking their place. Along those same lines, folks wonder if the interest in Classic British could be dying out with the aging original owners.

I have two counter points to those fears.

One, here at BCR we see a lot of customers and yes, many are silver-haired and mature, like me. We also see 30-40 percent of our clients who are the younger folks.

Ok, stop right there! Everything is relative, I am 74 so younger is 40-50! So, for instance, I am talking about those young enough to be really proficient at computers and cell phones. There is a percentage of the new clients that are even in their 30`s. These folks are excited to pick up the mantle and carry forward in taking care and loving these classics.

Two, To answer the mechanical question, we here at BCR we committed to the long term future of Classic British ownership and driving. Currently, we have me, the dinosaur, Christopher my son, who is the succession plan in completion, Chasen and Sulley who are both in their 20`s and for this summer we have an apprentice who is barely 19! Definitely a mix for the future of caring for the British Classics.

So, let me introduce you to Cooper, our summer apprentice and the young star caretaker on the horizon. He has the desire and enthusiasm to learn all about these British Classics and turn it into a lifelong career.

So, Cooper knew us from an even younger age. So he completed his first year in the McPherson program and was required to do a summer apprenticeship in a professional shop environment, he chose us to spend the summer learning the inside story from a classic full service to complete restoration shop.

Cooper is enrolled in McPherson college in Kansas. McPherson is the only accredited 4-year automotive restoration school in the USA. There are lots of 2-year programs, Wenatchee has one and that is where we recruited Chasen and Sulley. McPherson teaches all the topics required to be successful in the restoration field and in depth. Mechanical rebuilding, painting and body, upholstery, and business administration to mention just a few. There are 50 students in his class alone, and that many more in the second, third- and fourth-year levels. That is a great hope for the future of caretakers for our Classics!

Coopers` family lives in Washington and his grandfather had a Healey in for restoration. Then his father had a Healey in for restoration. Here is the grandparents and Cooper and his Dad`s car.

We have been showing him all aspects of being a professional mechanic, what it requires to be successful and what will be expected of him when he joins a shop full time. At the end of July, he will be returning to Kansas and entering the second year of instruction.

We are glad he is here and wish him great success going forward.

Steve, Laurie, Christopher, Dana, Chasen, Sulley, Mike, Eric & Mini

The dream

The memories

Reality